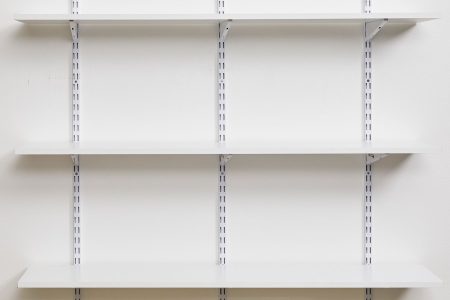

Wall shelves can be installed easily using metal standards and brackets. This hardware is readily available, inexpensive, strong, easy-to-install, and adaptable to a wide range of shelving options. Metal shelving standards and brackets can be used for bookcases, desks and other workspaces, media centers, and closet storage systems.

These systems work by means of metal standards attached vertically to the wall with screws driven into studs. Brackets are then placed in the standards to extend out horizontally to support the shelves. Several types of standards and brackets are available; some are appropriate for light-duty use and others suitable for very heavy-duty uses. For most applications, the double-slotted, heavy-duty products are the best choice. You can usually find these in different finishes at big-box stores such as Home Depot or Lowe’s, at hardware stores, and from online retailers.

Standards and brackets are available in a wide range of sizes; the widest selection is offered through online suppliers.

What You’ll Need

Equipment / Tools

- Stud finder

- Cordless drill

- 4-foot level

- Awl

Materials

- Painter’s tape

- 2-inch drywall or wood screws (with coarse threads)

- Standards and brackets

Instructions

-

Plan the Project

It is always a good idea to start a project with the finished goal in mind. Once you decide on a suitable wall for your shelves, sketch your plan. You’ll need to decide how high and low you want the top and bottom shelves, how many shelves you need, and how long the shelves will be.

With that settled and a rough sketch in hand, you can shop for all the materials you need. Plan to buy standards about 10 to 12 inches longer than the intended distance between the top and bottom shelves. This will give you some flexibility in the arrangement of the shelves.

When you move, the whole shelving assembly can be disassembled quickly. Fill and paint the holes in the wall to leave things just as they were before the shelves were installed.

-

Locate Studs

First, use a stud finder to find wall studs. The standards must be anchored with screws driven into studs—the vertical framing members to which drywall is attached. The studs should be spaced 16 or 24 inches apart in the wall, measured center to center, although additional studs may appear within the spacing pattern near doors, windows, and corners.

Use a battery-operated or magnetic stud finder to locate the studs in your wall. The former tool will locate the studs behind drywall by detecting density, while the latter tool works by sensing the nails or screws that hold the drywall to the studs.

Move the stud finder straight across the wall, marking each stud location. Rather than a pencil, use small pieces of blue painter’s tape to mark the location of each stud. When you’re done, you can remove the tape without leaving any mark behind.

-

Plan Locations for Shelf Standards

With the studs located and marked, the next step is to determine the best spot to install shelf standards. For basic bookshelves, plan to set the standards 32 inches apart if the walls have studs spaced 16 inches apart. If your studs are spaced 24 inches apart, plan to attach a standard to each stud.

Shelves should overhang the side brackets by no more than 6 inches. So, for example, if you plan to use three standards spaced 32 inches from each other (total span of 64 inches from end to end), you can safely use shelves that are as much as 76 inches long (or a standard 72-inch, 6-foot-long board would work fine).

For particularly heavy loads, check the manufacturer’s instructions to determine the best spacing for your standards.

-

Attach the First Shelf Standard

It is easiest to attach shelf standards with a helper, although it’s possible to do the job yourself.

Set the first standard in place at the intended height, centered over a stud. When you are satisfied with the location, stick an awl through the top screw hole in the standard, marking a small indentation in the wall. This will make it easier to set and drive the screw.

Drive a screw through the top hole, just deep enough to hold the standard in place securely; don’t make it so tight that you can’t move the standard a little. Set your level alongside the standard, adjusting the position so that it is perfectly plumb (that is, vertical). Plumb is indicated when the bubbles in the top and bottom vials are centered.

Poke awl holes and drive screws into each remaining screw hole location in the standard, making sure it’s positioned perfectly plumb. The standards should be just barely snug against the wall; if you drive the screws in too far, you may damage the wall surface.

-

Attach the Remaining Shelf Standards

The shelf standards must be installed plumb, but it is equally important that the brackets, and therefore the shelves, are level across the standards.

Set a level across adjacent brackets, sliding the standard up and down until the bubble in the center vial is centered. Make sure that the standard is resting over a stud, then punch a hole in the wall through the top screw hole and drive a screw.

Use a level to make sure the standard is plumb, then attach the standard to the stud with screws. Repeat the process for any remaining standards.

-

Attach the Shelf Brackets

Shelf brackets range in size from 5 inches deep (for shelves holding paperback books) to 24 inches (for desktops and other large spaces). Plan to use brackets that are just a bit shorter than the depth of the shelves. For example, if the desired shelf is 12 inches deep, the supporting legs of the bracket must be at least 8 inches but no more than 11 inches.

You don’t have to make all shelves the same depth. Instead, you can install shelves that get increasingly deeper from top to bottom, allowing you to place smaller items on top and bigger items on the bottom, or the other way around.

Slip the bracket into the slots on the standard, then give it a little push down to make sure it’s set properly. A tap with a mallet or hammer is sometimes necessary.

-

Attach the Shelves

You can buy shelves ready-made or you can make your own. There are several options.

- Solid wood is the strongest choice and the one that works best if loading books on brackets and standards spaced 32 inches apart. Shelving that spans 24 inches can be safely made from wood, plywood, melamine, and medium-density fiberboard (MDF).

- Wire shelves are available in light- to heavy-duty options.

- The least expensive shelving option is to buy large 4 x 8-foot sheets of 3/4-inch plywood or MDF and cut your shelves to size. Often you can have the sheets cut to size (or at least to a size that you can haul home) at the lumberyard or home improvement center.

Pre-cut melamine (that glossy white plastic surface so common in kitchen cabinets) does not require any additional finish. The other materials should be painted or, in the case of solid wood and plywood, sealed with a clear wood finish.

-

Enclose the Shelf Ends (Optional)

To ensure that books and other items don’t fall off the shelf ends, simply to stack books on their sides at the ends of the shelves. Another method is to use the special bookend brackets that slip neatly into the slots in the standards.

Bookends are available in several sizes. To use bookends on the top shelf, the shelf must be set at least 6 inches below the top of the standards.

Read the full article here